Ke Xun Ge Oboe Profiler

Howarth of London are pleased to stock the Ke Xun Ge Oboe Profiling Machine. Ke Xun Ge prides himself on having produced a machine capable of completing a reed to a fully finished state. The machine can be adjusted in various ways to allow for variations in cane density and reed aperture. The user can also affect the scraping outcome by applying differing amounts of pressure to the blade. The machine’s computer-designed template helps to create perfectly balanced reeds, and the German template can also be used for making cor anglais reeds.

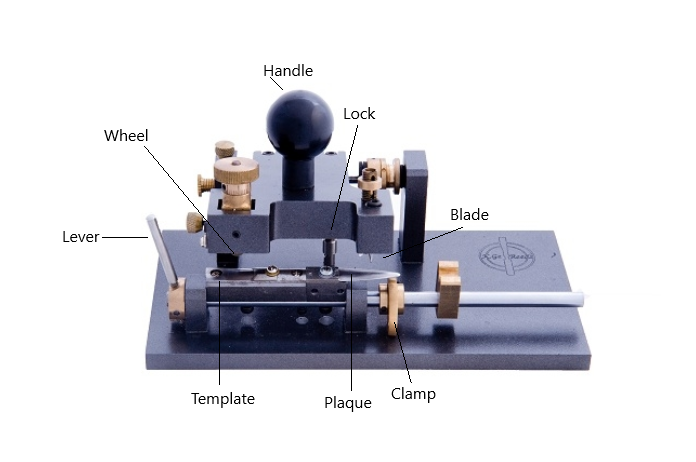

Parts of the Machine

The profiler has a wheel which travels over a template to read it. This wheel is attached to a carriage which travels forwards and backwards. This part of the machine also contains a circular blade, the tension of which can be adjusted to control how much force is exerted downwards on the reed whilst it is being scraped. The reed is placed onto a fixed plaque and clamped to hold it still. A locking device attached to the machine’s base keeps the carriage still while it isn’t in use, protecting the machine from damage. A lever allows the user to rotate the template and plaque to scrape the centre and sides of the reed.

How to Use the Profiler

- Find the locking device on the base of the machine holding up the carriage. Lift the metal ring at its base and lay the spoke on its side.

- Before starting to profile your reed blank, cut off the tip to the desired finished reed length. Slide the reed onto the plaque up to the line, ensuring it is placed centrally. Hold the reed still on the plaque with your left hand and use your right to bring the clamp across the reed to secure it in place.

- Gently lower the carriage onto the reed and begin by lightly scraping the tip. Use the lever to rotate the arm holding the reed from side to side so the blade can evenly scrape the reed.

- When most of the desired cane has been removed from the reed’s tip, scrape the rest of the lay exerting even pressure downwards onto the carriage and blade. When cane no longer comes off, you are finished.

- Remove the clamp, turn the reed over on the plaque and repeat the scraping process on the second blade. There will be a mark on this blade which will guide you as to where to place the reed on the plaque.

Possible Adjustments

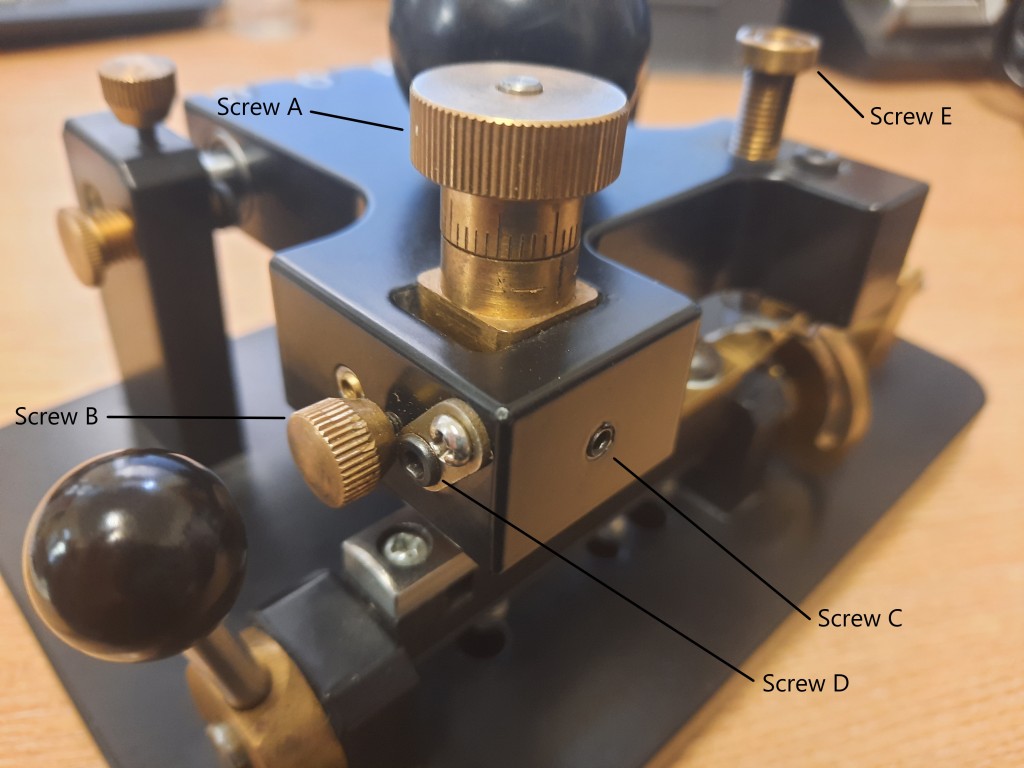

- To adjust the overall amount of cane scraped from the reed, rotate screw A anti-clockwise to take more cane from the reed, and vice versa. Screw B locks Screw A into place.

- To adjust the tip length, release locking screws B and C. Screw D can then be turned clockwise to lengthen the tip, and vice versa. Retighten the locking screws when finished and adjust the amount of carriage travel as necessary.

- To adjust the amount of cane taken from the back of the reed, alter the tension of the spring behind the blade (E). If you want to take more cane from the back of the reed, reduce the spring tension by turning Screw E anticlockwise.

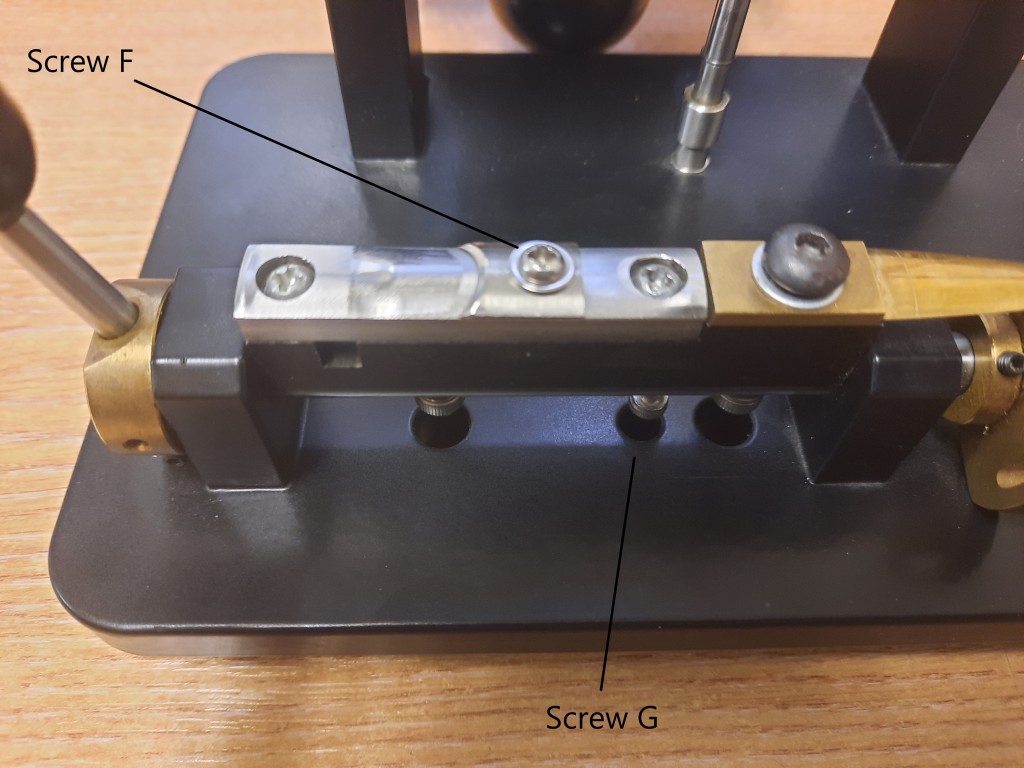

- To adjust the length of scrape, unscrew F and slide the piece of metal forwards/left to shorten the length of scrape or backwards/right to lengthen it.

- To adjust the machine for different gouges of cane, use Screw G. Turning this will change the angle of the template. Turning the screw clockwise will lift the template, which will work better for cane with a thicker gouge.

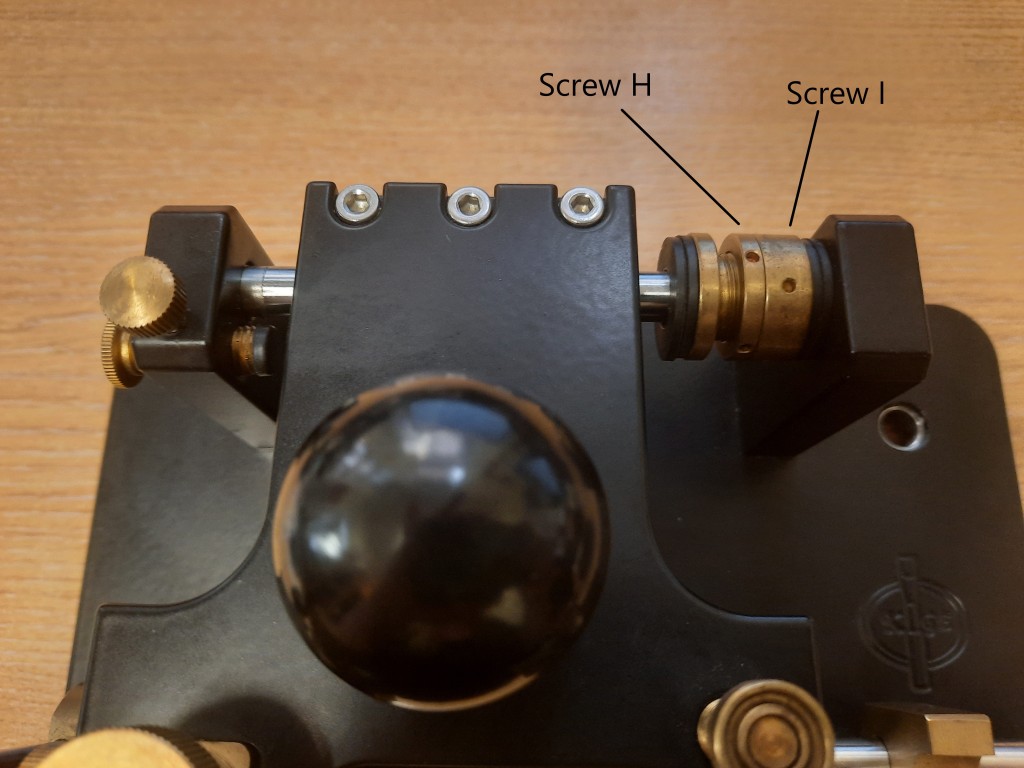

- If you have adjusted the length of scrape as detailed above, you may also need to adjust the distance the carriage can travel to ensure the wheel can travel enough to read the entire template. Adjust the carriage travel distance using the gold rings marked Screws H and I on the diagram.

If you would like further information regarding the Ke Xun Ge Oboe Profiling Machine, please email us at [email protected] or call our London Showrooms on 02079352407.

Bethany Craft, Oboe Specialist- Howarth of London