Reeds ‘n Stuff Oboe Shaping Machine

Many advanced oboists choose to make their own reeds so that they can tailor them to their own individual preferences. Whilst some oboists make their reeds using cane that has already been gouged and shaped commercially, others like to have control over more stages of the reed-making process. Machines such as Reeds ‘n Stuff’s oboe shaping machine make it easier and more efficient for individuals to shape gouged cane to their preferred dimensions.

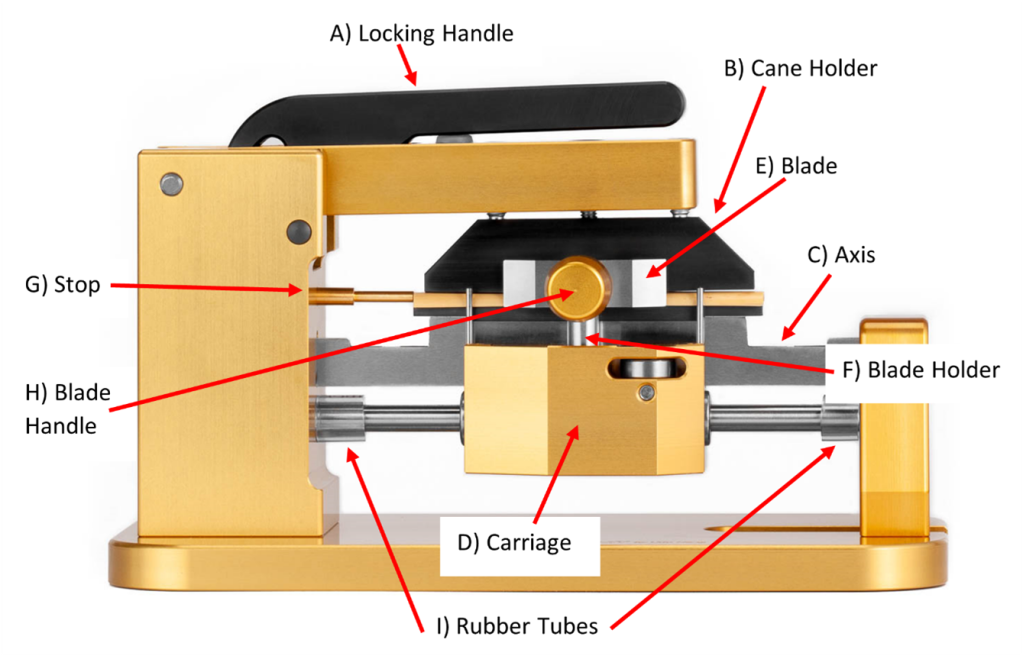

This shaping machine is formed of a locking handle (A) and a cane holder (B) (which together form a ‘locking arm’), an axis (C) which holds a shaper form and the cane, and a carriage (D) with attached blades (E) which is manually pushed along the axis to shape gouged cane.

Instructions for Use

Soak the gouged cane for 1-2 minutes before starting to shape it. If you begin to shape the cane and a lot of force is required to shape it or it starts to crack, soak the cane for longer.

- Securely fix the machine to a surface using the C-clamp supplied with the machine.

- Push back the locking arm (locking handle and cane holder). Remove the protective foam from between the cane holder and the shaper form.

- Insert the blade holders (F) into the receivers in the centre of the carriage.

- Position the gouged cane centrally on the shaper form with the inside of the cane facing down and the outside facing upwards. The supplied centring pins can help to align the cane if needed. Push the cane backwards until it meets the stop (G).

- Pull the cane holder onto the cane, ensuring the cane’s position doesn’t change. Push the locking handle backwards so that the cane holder is locked in place and the cane is scored in its centre.

- Slide the carriage as far away from you as possible and take a blade handle (H) in each hand. Using a light pressure, press the blades against the shaper form whilst pulling the carriage towards you. Stop when the blades reach the front end of the shaper form.

- Now with the carriage as far forward as possible and with the opposite sides of the blades against the shaper form, push the carriage backwards using the same motion as before, stopping when the blades meet the back end of the shaper form.

- Repeat steps 6 and 7 to ensure there is no cane left protruding from the sides of the shaper form.

- Release the locking handle and push back the locking arm to remove the now shaped cane from the machine.

Shaper Forms

The price of the shaping machine includes one shaper form of your choice, manufactured using the latest CNC technology to ensure absolute symmetry. Reeds ‘n Stuff offer a wide variety of shaper forms to suit individual needs, and the machine fits all brands of shaper forms. There is even the option for Reeds ‘n Stuff to produce your own bespoke form.

Adjustments

Carriage Travel:

The carriage’s level of travel must correspond with the length of the shaper form used. The blades should be allowed to travel exactly to the back end of the shaper form without cutting into the stop and exactly to the front end of the shaper form without the blades meeting. If the shaper form is changed, the rubber tubes (I) on the axis may need to be adjusted to a different length (a spare tube is supplied for this).

Blades:

The height of the blades can be altered by turning the screws at the bottom of the blade holders. Adjusting the blades’ heights changes the section of the blade in contact with the cane. This gives the blades the longest possible lifespan as several sections of them can be utilised.

The blades can easily be changed by removing the blade holders from the carriage and removing/replacing the screws from the blades with the hex key supplied.

One side of each blade holder is intended for shaping oboe cane and the other for shaping cor anglais cane, so the blades must be fitted to the sides appropriate to the work being carried out. The back of the blades should face the side of the blade holder with the suitable oboe or cor anglais engraving and fixed in place with the screws.

Reed-making machines can be invaluable for oboists wanting the ability to produce reeds quickly and easily with a high level of consistency and control. Reeds ‘n Stuff’s oboe shaping machine is intuitively and ergonomically designed, making it simple to handle and easy to produce precise results. The machine is manufactured using high-quality materials guaranteeing longevity, e.g. the blades are made from high carbon steel, and the wide range of available shaper forms allows the user to shape cane to suit their individual requirements.

For more information about the machine, please contact us at [email protected] or 020 7935 2407.

Bethany Craft, Oboe Specialist – Howarth of London